Process Optimization

In mass production, cost savings are continuously required.

Product cycle times are shortened, e.g. in the automotive industry. Production

plants are under increasing pressure to plan new production starts and optimize existing

component production to increase productivity. In addition, the component requirements in regards to dimensional accuracy, hardness zones, surface qualities and fine waviness continue to increase.

For example, in a precision grinding process, there are 125 influencing factors that affect the result. The same obtain in many other processes.

My service offer for process optimization is mainly aimed at the metal-cutting industry.

The vibration diagnosis for machining processes is hardly described in literature. There are typical vibration signals which are similar for different machining processes and which can be used for diagnostics, for example problems with chatter marks, or also for increasing the cutting performance, service life extension and the comparison of machines.

Many measurements can be done in the ongoing production process and possible improvements like parameter adjustments or other changes in the process can be directly verified.

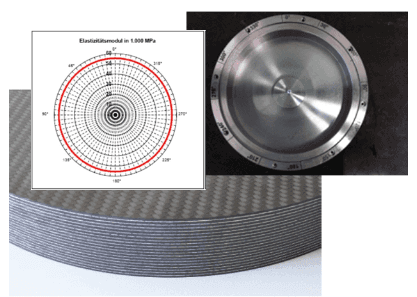

For the development of cutting tools, for instance rotating body for bonded abrasive or drilling, turning, and milling tools I can perform a modal analysis of prototypes. Thus, the modal variables mode shape, natural frequency and damping can be determined, and integrated into an animated computer-aided model. This can also be used to optimize your FEM model. As a result, targeted development for various applications can be operated.

Also take the advantage of the opportunities with fiber composites to develop tools with high damping factor and rigidity for maximum performance. Gladly I advise and support you.